Clad steel ... effective solution in highly corrosive environment

Clad steel ... effective solution in highly corrosive environment

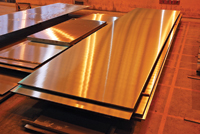

FOR carbon steel in contact with hydrogen sulphide (H2S), a good resistance is provided by a combination of improved chemistry, cleanliness, homogeneity and microstructure. Industeel developed its family of carbon-manganese (C-Mn) CarElso grades of steel in order to satisfy the requirements for plates from six to 200 mm thick and beyond.

A sample-averaged crack length ratio (CLR) of maximum five per cent is commonly achieved whereas excellent individual specimen CLR values down to also five per cent can be guaranteed for the thinner and seven per cent for the thicker ranges, thanks to the high level of homogeneity of the steel. More than 15,000 tonnes of sulphide stress cracking (SSC) and hydrogen induced crack (HIC) resistant Industeel CarElso are delivered yearly.

Steelmaking includes vacuum ladle refining after electric arc furnace melting of selected scraps, to enable the making of very clean high quality C-Mn steel.

At the final stage of fabrication, proper post weld heat treatment (PWHT) of the entire equipment is highly recommendable. A 595-deg C to 610-deg C range is necessary and sufficient to achieve proper mechanical properties, hardness level, and H2S resistance for C-Mn normalised grades typically according to ASTM A516 or ASME SA516 standards and produced by Industeel.

To facilitate specification and procurement, Industeel has assembled its know-how to fine-tune an optimised standard offer under the brand CarElso HIC Premium+, available from the mill as well as from selected distributors worldwide.

For more severe application, corrosion resistant alloys (CRAs) can be used for the control of corrosion in oil and gas systems and have a number of benefits. For instance, savings can be made in operating costs since corrosion inhibitor injection is not required and in inspection and maintenance costs compared to a carbon steel production system with or without internal organic linings. Thus, if a life-time costing approach is taken, CRAs can often be shown as an economic corrosion control option for oil and gas production system. Nevertheless, CRAs contain expensive allowing elements, particularly the more highly alloyed materials required for corrosive sour production systems.

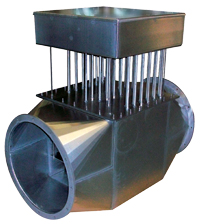

Clad steel is a composite product developed to provide effective and economic solution in highly corrosive environment. The cladding layer, which will be in contact with the corrosive fluids, is made of a CRA whilst the less expensive backing steel provides the strength and toughness required to maintain the mechanical integrity.

The bond quality is controlled by a 100 per cent UT of the plate surface, and also by a shear resistance test.

Industeel is a world renowned clad supplier, producing clad plates since more than 50 years. Cladding can be ferritics, standard austenitics, duplex, super austenitics or nickel base alloys. Backer steels are generally CMn or CrMo types.