Sabic’s Ultem finds applications in healthcare systems

Sabic’s Ultem finds applications in healthcare systems

Sabic has worked with Brazil’s Indusbello to develop a differentiated solution using Ultem HU1004 resin

Sabic’s Innovative Plastics business continues to develop materials with properties that can contribute to protecting both staff and patients from infection.

Working closely with customers to understand their challenges has led to several key solutions, including materials with enhanced sterilisation performance, materials with antimicrobial properties and materials that meet a wide range of chemical resistance requirements which can withstand more aggressive cleaning.

The intensifying focus on the range of processes used to sterilise medical and dental equipment and devices continues to grow. Trends in the industry are pointing towards designing more inherent functional capabilities into reusable devices, meaning that they are more likely to contain sensitive electronics (vulnerable to heat and moisture) or other features which could require different sterilisation options.

Materials must now be able to withstand a number of different sterilisation processes which have the potential to degrade devices over time, diminishing their mechanical integrity, interfering with performance, or altering their aesthetics.

Resin material technologies such as Sabic’s Ultem HU1004 resin have evolved to help answer this need for enhanced protection and can be a significant factor prolonging the life of expensive medical and dental equipment by enabling it to better withstand intensive sterilisation processes.

Medical devices can be subjected to a variety of sterilisation processes, including gamma radiation, hydrogen peroxide gas sterilisation (a low temperature sterilisation process) and high temperature steam autoclave (up to 134 deg C). Ultem HU1004 resin, a thermoplastic polyetherimide (PEI) material, has proven capabilities in each sterilisation environment.

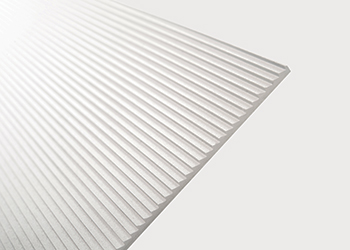

Sabic has worked closely with Indusbello, a medical device manufacturer in Brazil, to develop a differentiated solution using Ultem HU1004 resin for sterilisation trays to help improve the safety of patients and clinician healthcare environments. Pre-assessed for biocompatibility per ISO 10993, this material can also provide flexibility in design, transparency, superior aesthetics and enhanced productivity through injection molding.

For opaque applications such as sterilisation tray bottoms where mechanical and physical property retention may be higher in priority than colour aesthetics, Noryl HNA055 resin offers impact resistance, dimensional stability, chemical resistance, hydrolytic stability and strong property retention after steam sterilisation at both 120 deg C and up to 134 deg C.

The repeated wipe down of medical equipment with increasingly aggressive disinfectants to prevent the spread of HCAIs is putting devices at risk for substantial wear and tear known as environmental stress cracking (ESC).

ESC in medical devices as well as structural applications such as hospital bed components, can be related to many factors including polymer morphology, chemical concentration and residual stress in moulded components.

Sabic’s range of engineered thermoplastics has been developed to help medical device manufacturers meet challenging chemical resistance requirements. Enhanced chemical resistance performance test data which includes results from an ESC resistance study, shows the performance of Sabic’s materials when repeatedly exposed to aggressive disinfectants.

The study looks at compatibility of common flame resistant medical enclosure materials tested with alcohol / quaternary ammonium compound (QAC)-based disinfectants and alcohol-free / QAC-based disinfectants, which are commonly used disinfectants to help prevent the spread of infections.

Designing healthcare applications with materials that can reduce the potential transfer of pathogens is another approach to help control the spread of infection.

Sabic has developed a range of LNP antimicrobial thermoplastics compounds.