The plant will manufacture high-performance polyethylene products using the Nexlene technology

Sabic and South Korean petrochemical company SK Global Chemical have inaugurated a $640 million polyethylene plant in Ulsan, South Korea.

The plant was established through Sabic SK Nexlene Company (SSNC), a 50/50 joint venture based Singapore.

SSNC’s wholly-owned subsidiary, Korea Nexlene Company (KNC), will operate the plant, which has an annual capacity of 230,000 tonnes.

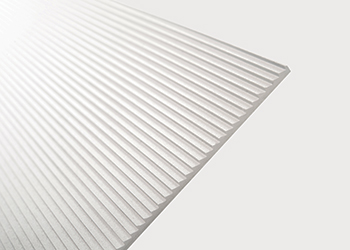

The plant will manufacture high-performance polyethylene products using the Nexlene Solution Technology.

It will produce metallocene linear low density polyethylene (mLLDPE), polyolefin plastomers (POP) and polyolefin elastomers (POE) that will meet the growing needs of diverse industries such as advanced packaging, automotive, health care, footwear and electrical and lighting. This magnificent new industrial facility will enhance the petrochemical industries through innovating world unique solutions utilising Nexlene technology," says Sabic chairman Prince Saud bin Abdullah bin Thenayan Al-Saud.

"Through this cutting-edge technology we will be able to meet our customers’ needs around the world, through a more advanced, high value, and unique, customer-focused selection of products."

We are very pleased to take this latest step in our partnership with SK Global Chemical, which further expands Sabic’s presence worldwide," says Yousef Al-Benyan.

In addition to the new plant, Sabic and SK will inaugurate new research and development facilities in Daejon, South Korea. It will feature departments focusing on process development, as well as catalyst and product development.

The centre will also sponsor and oversee research programmes at universities and third party facility in Korea and around the world. These new facilities mark the latest Sabic investments in manufacturing and research in the Far East after its partnership with the China Petrochemical Corporation (Sinopec) and the Sabic Technology Center in Shanghai, which was inaugurated in 2013.