Aramco lays stress on the production of non-associated gas

Aramco lays stress on the production of non-associated gas

Saudi Aramco plans to nearly double its supply of gas over the coming decade to more than 20 bscfd, taking clean gas to more than 70 per cent of its utilities fuel mix – among the highest rates in the world

Decades ago, natural gas was viewed as a less valuable byproduct of crude oil production, but beginning with the creation of the Master Gas System in the early 1970s, Aramco has harnessed the power of natural gas to spur the diversification of the kingdom’s economy.

Its latest gas plant, Wasit, is designed to process 2.5 bscfd of nonassociated gas and supply 1.7 bscfd of sales gas to the Master Gas System, fuelling electrical power and seawater desalination plants and supplying feedstock for the petrochemical industry.

Its continued success in increasing supplies of cleaner burning natural gas makes it possible for the company to reduce emissions, enable new industries, and release more crude oil for value-added refining or export.

Wasit’s design reflects its plan to become self-sufficient in power generation. By converting waste heat to steam, Wasit has the capacity to generate 798 megawatts of power.

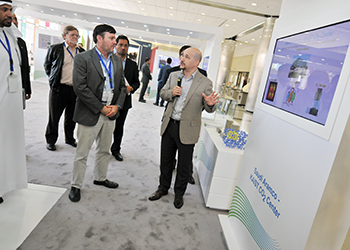

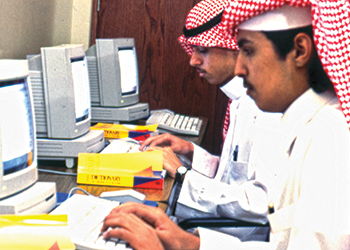

This process, known as cogeneration, allows the company to produce electricity as a byproduct of its operations. Less fuel is required to produce energy and less fuel is consumed, thereby lowering emissions. Behind the power of cogeneration is the power of people. Its employees oversaw the design and construction of the cogeneration plant. All the members of the cogeneration operations team are Saudis, many of whom are young graduates of its Apprentice Programme.

This youthful team shouldered a big responsibility – the cogeneration plant had to deliver power and steam to support the commissioning activities preparing Wasit to come onstream. Wasit, combined with the other gas plants in the Master Gas System, enables the company to process more than 11 bscfd, delivering on its commitment to safely and sustainably power progress and prosperity.

Aramco made significant progress towards completing the expansion of its Shaybah field to increase production of Arabian Extra Light crude oil by 250,000 bpd, raising overall production capacity to 1 mbpd. The project is on track to come onstream in the first half of 2016.

In addition to its large-scale oil production projects designed to meet anticipated future demand, Aramco sustained its Maintain Potential programme. For example, in 2015 its largest offshore tie-in platform, weighing in excess of 6,000 metric tonnes and too large for standard marine cranes, was installed in Safaniyah using an innovative "float over" method.

The platform serves as the main crude oil gathering and power supply hub for North Safaniyah and was energised through the laying of a 46 km, 230 kilovolt submarine cable – the longest of its kind in the world installed as a single piece without a field splice.

GAS PRODUCTION AND PROCESSING

|

Gas operations are getting a lift |

Aramco’s ability to increase supplies of natural gas to reduce the kingdom’s reliance on liquid fuel for electricity generation and to power seawater desalination plants is vital for the country’s continued prosperity.

To meet this challenge, Aramco plans to nearly double its supply of gas over the coming decade to more than 20 bscfd, taking clean gas to more than 70 per cent of its utilities fuel mix – among the highest rates in the world.

In 2015, Aramco achieved a record for raw gas processing, averaging 11.6 bscfd. Greater volumes of gas mean more feedstock for industries to expand and new ones to emerge, helping to drive the creation of new jobs. The increased use of cleaner burning natural gas in the kingdom’s fuel mix also brings with it environmental benefits in the form of lower emissions. Wasit Gas Plant, one of the largest nonassociated gas plants Aramco have ever built, came onstream in October. The plant will be fed with nonassociated gas from offshore fields, ultimately reaching 2.5 bscfd.

Wasit will have the capacity to produce a maximum of 1.7 bscfd of sales gas and fractionate 240,000 bpd of NGL. Once it reaches full operating capacity in mid-2016, the addition of Wasit to its portfolio will represent a significant increase in its gas processing capacity.

The cogeneration plant at Wasit makes the facility self-sufficient in power, with excess energy delivered to other company plants. The NGL recovery plant at Shaybah was commissioned and started NGL production in December. Designed to process as much as 2.4 bscfd of associated gas and recover 275,000 bpd of ethane plus NGL, the Shaybah facility will feed these new volumes of NGL via pipeline to Ju’aymah for further processing before being delivered as petrochemical feedstock to industrial cities.

Construction of gas processing facilities at Aramco’s Midyan Gas Plant in the Tabuk region of northwestern Saudi Arabia was roughly 50 per cent complete by the end of 2015. Aramco anticipates bringing the plant onstream by the end of 2016, with the capacity to produce and process 75 million scfd of nonassociated gas and 4,500 bpd of condensate.

The plant will deliver sales gas and condensate to power the Saudi Electricity Company’s new Duba Power Plant, a high-efficiency plant that will combine solar power with energy generated from the fuel supplied by Midyan.

Together, its gas plant and the power station will spur economic development in the area, generating opportunities for training, job growth, and new businesses.

EFFICIENCY GAINS

By maintaining an unwavering focus on securing more value from the kingdom’s hydrocarbon resources while exercising fiscal discipline, Aramco attained substantial gains in capital and operating efficiencies across its upstream activities.

Aramco used the market downturn to renegotiate contracts to achieve significant cost savings for construction and equipment, and for services related to drilling, well stimulation, testing, and logging, even while rig count numbers declined globally across the industry.

Through more efficient well designs, Aramco was able to increase the average daily drilling depth of new gas wells by 21 per cent, enabling faster well completion times and driving costs down. Revitalising existing vertical wells through drilling horizontal extensions – or sidetracks – improved the crude oil production rates of older wells.

This technique extends the operational life of oil wells, deriving additional value from existing assets by lowering drilling costs, utilising existing flow lines, and shortening tie-in time. Not all efficiency gains are technology driven: Aramco optimised 52 tests and inspections of major facilities to align with the needs of customers to maximise the delivery of products while also minimising the burning of liquids for power generation.

Aramco eliminated the use of drilling rigs to replace downhole gauges by deploying gauges retrievable by wirelines in its offshore Marjan, Safaniyah, and Zuluf fields. This rigless approach is safer and also delivers significant cost savings by freeing up drilling rigs for other work. Aramco is evaluating this method for possible deployment in other fields.