The voestalpine Böhler team at a previous edition of Adipec

The voestalpine Böhler team at a previous edition of Adipec

The firm relies on committed employees who have been trained to the highest standards. It is their knowledge, skills, and personal commitment that ensure the long-term success of the company and its customers

Voestalpine Böhler Welding (formerly Böhler Welding Group), a leading manufacturer and worldwide supplier of filler metals for industrial welding and brazing applications, will be promoting its high-quality welding products at Adipec 2016, which is a "strategic venue" for the company.

With more than 100 years of experience, the company has decisively influenced the development of welding technology, setting the benchmark with its innovative solutions. The solidity is also reflected in the confidence of its employees who, as owners of the enterprise, hold a good portion of the shares, says Anders Andersson, managing director of voestalpine Böhler Welding Middle East FZE.

"We are continuing our successful expansion in the Middle East and emerging markets including India, where the company has newly acquired a manufacturing facility," says Andersson.

"Moreover, we were the major supplier of welding consumables for Abu Dhabi’s Zakum project. Currently we are major supplier for the Clean Fuels Project, Lower Fars Heavy Oil project, Al Dabbiya and the Jizan Refinery Expansion Project," he says.

CUSTOMER FIRST

Absolute customer focus is the company’s guiding principle. "We see ourselves as a provider of solutions to challenging welding projects. We ensure that our customers get the right filler metals, use them correctly, and that all welding process parameters are adjusted for the best possible performance.

"We consider it as our responsibility to guarantee that we deliver to our customers, now and in the future, the best possible solutions. We also strive to develop new products, optimise existing products, and streamline processes so as to achieve very short turnaround times," he says.

|

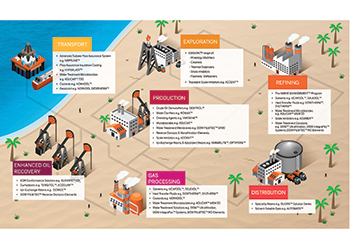

voestalpine Böhler’s plethora of products |

THREE COMPETENCIES – THREE BRANDS

In its efforts to afford its customers the best possible support and promote development in line with specific targets, Böhler has built its core competences within joint welding, repair and maintenance welding and soldering and brazing. This way the company offers its customers the largest and most comprehensive product portfolio of filler materials within its three brands:

Böhler Welding: Creating lasting connections is the most important part of the welding process. More than 2,000 products for joint welding in all conventional arc welding processes are now united under the Böhler Welding brand in a product portfolio that is unique throughout the world. Therefore its customers benefit even more from its personal application consultations, because the company is also past masters at creating connections between people as well.

UTP Maintenance: Decades of industry experience and application know-how in the areas of repair, wear and surface protection in conjunction with innovative and tailored products guarantee Böhler’s customers an increase in the productivity, protection, service life and performance capacity of their components under the UTP Maintenance brand.

Fontargen Brazing: "As an insider, we have insight into processing methods and understand how to apply them as the essential factor for optimum soldering results. Our expertise has been formulated over many years of experience providing solutions and the knowledge gained from countless application challenges," he says. The Fontargen Brazing brand offers one knowledge and application experience for one’s soldering processes on the basis of proven products – Engineered in Germany.

EXPERIENCED EMPLOYEES

Böhler relies on committed employees who have been trained to the highest standards. It is their knowledge, skills, and personal commitment that ensure the long-term success of the company and its customers. In combination with its premium quality products, the individual technical support provided by the company’s globally acting application technicians and specialist welding engineers empowers its customers to master even the most difficult and challenging welding tasks.

"We focus on industries with high technological standards and deliver products tailored to industry-specific requirements. In the development and optimisation of filler materials, we collaborate closely with customers, manufacturers, and research institutes," he explains.

Whether destined for use in challenging scenarios or in standard applications – Böhler’s high quality filler materials are ideally suited for all applications in the following industry sectors: Oil and Gas, Pipeline, Chemical, Power Generation, Transportation and Automotive, Maintenance and Repair and Brazing Industries.

voestalpine Böhler Welding enjoys worldwide representation, with 40 subsidiaries in 28 countries. The company services customers in more than 120 countries, either directly or indirectly.