EVOLVING global regulations and growing numbers of patients seeking high quality care are driving the healthcare industry to continuously look for new ways to enhance safety throughout the industry value chain.

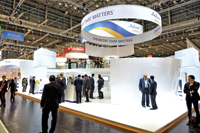

At K 2013 in Dusseldorf, Germany recently, Sabic showcased a relevant portfolio of engineered thermoplastics and polymer technologies that can help enhance the safety for care-givers and patients.

Whether it’s helping prevent infections with the company’s portfolio of antimicrobial compounds; enhancing dosing accuracy with syringe barrels that benefit from exceptional clarity; or helping to preserve medication shelf life and protect them from contamination using Sabic’s advanced polymer technology, the Sabic applications on display at this year’s K Show demonstrated the company’s commitment to helping its customers continue to advance safety in the healthcare industry.

“Increasingly, in healthcare environments, minimising Healthcare Associated Infections (HCAIs) has been a major challenge for our customers. As a result, Sabic continues to develop robust solutions that empower our customers to keep pace with the rapidly growing challenge of infection control.

“Sabic’s engineering thermoplastic technology with antimicrobial additives and materials with enhanced sterilisation performance are two of Sabic’s recent developments which can be used within the healthcare industry to help decrease the spread of infection,” says Cathleen Hess, director of Healthcare Marketing for Sabic’s Innovative Plastics business.

To help enhance patient and clinician safety in healthcare environments, Sabic is committed to helping reduce Healthcare Associated Infections (HCAIs).

According to the World Health Organisation, of every 100 hospitalised patients at any given time, seven in developed countries and 10 in developing countries will acquire at least one HCAI.

Sabic has responded to this challenge with a range of LNP antimicrobial thermoplastic compounds, using silver-based antimicrobial technology, as silver is well-suited to diverse applications and accepted as a broad-spectrum antimicrobial, with activity against multiple pathogens.

With four different base resins and two different levels of antimicrobial effect, Sabic has one of the broadest portfolios of antimicrobial materials, allowing device designers and manufacturers the freedom to meet the strict requirements of the healthcare industry, while helping to enable the prevention of HCAIs.

Sabic’s customisation capabilities have resulted in a myriad of potential antimicrobial solutions which include fluid and drug delivery applications, surgical instruments, monitoring and imaging devices and durable medical equipment such as hospital beds and operating tables. Sabic’s recent collaboration with Indusbello resulted in a differentiated solution for sterilisation trays using Sabic’s Ultem HU1004 resin, a polyetherimide (PEI) resin blend with enhanced hydrolytic stability.

This technology is designed to withstand a number of harsh sterilisation processes, including hydrogen peroxide, required in cleaning medical devices to help reduce infections, while providing flexibility in design, transparency, superior aesthetics and enhanced productivity through injection moulding.

“As a result of the diversity of our portfolio and in-depth industry knowledge, Sabic is uniquely positioned to collaborate with its healthcare customers around the world to help them meet some of the industry’s major challenges”, says Hery Randrianantoandro, segment leader Healthcare, for Sabic’s Polymers business in Europe. “The solutions in our portfolio help improve safety throughout the entire industry value chain.”

The healthcare packaging industry has an increasing demand for safe and high performing flexible material for packaging pharmaceuticals and medical products. The pouches and sachets – made out of this material – should not only preserve the packaged medicine but should also ensure safe use by the patient.

Sabic’s latest film range responds to this rising market need. This new range which includes Sabic HDPE PCG5009, Sabic LLDPE PCG0863F and Sabic LLDPE PCG6118NE helps optimise the seal and package integrity which ultimately results in an optimised preservation of medicines and an improved safety of medicine usage.

Moreover, these grades are fully tested in accordance with the relevant European Pharmacopoeia (EP) and United States Pharmacopoeia (USP) requirements to meet the needs in the pharmaceutical industry for an optimal quality and safety for their packaged drug products during shelf-life.

Within the healthcare profession, there is an increased demand for techniques to improve the accuracy, efficiency and precision in drug transfer. Sabic PP PCGR40 and Sabic PP PCGR40L are the company’s latest solutions within its polymer portfolio.

This clarified polypropylene (PP) material has an exceptional glass-like clarity that supports improvements in dosing accuracy and better detection of contaminants in medical applications.