Base station solutions

Base station solutions

This suite of new materials has been optimised for transmission conditions from 900 MHz to 3GHz and beyond, providing different combinations

The explosive growth of smart devices, mobile-to-mobile connected modules and the ever-increasing amounts of data and voice traffic generated by their use are key drivers in the need to expand global network and transmission capacity.

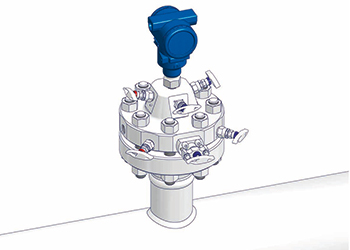

Sabic has developed new solutions to help manufacturers of base station antennas – in particular, internal components such as phase shifters – meet this demand with a new portfolio of Thermocomp compounds that have been engineered to meet specific performance requirements in ways that are superior to two incumbent materials, ceramics and PCBs.

This suite of new materials has been optimised for transmission conditions from 900 MHz to 3GHz and beyond, providing different combinations of Dk (dielectric constant) and Df (dielectric dissipation factor) performance.

And, according to Alan Tsai, director of Consumer Electronics Technology & Innovation, Innovative Plastics, "Because these are thermoplastic materials, they can provide greater design flexibility and higher manufacturing yield than traditional materials such as ceramics or printed circuit boards (PCBs), in addition to meeting specific signal strength or signal range objectives."

Within each base station are multiple antennas containing phase shifters which, based on traffic, deliver either greater strength, meaning fewer dropped transmissions; greater range, meaning a broader coverage area; or both.

Key measures of performance are the dielectric constant (Dk), which quantifies signal range, and the dielectric dissipation factor (Df), which indicates signal loss.

The dielectric performance requirements are slightly different at various frequencies from 900 MHz to 3GHz, and at different temperature ranges.

"We found that the industry lacked performance-specific materials," Tsai noted, "which is why we took on the challenge of providing new options."

In general, when compared to ceramics and PCBs, Sabic’s materials can provide a better balance of dielectric properties, with extremely low Df, down to 0.001, and a wide range of Dk from 3 to 13.9, depending on frequency requirements. By comparison, general purpose PCBs are capable of Df to 0.005.

In addition, the thermoplastic-based materials have mechanical properties that provide a number of advantages to base station component OEMs, such as dimensional stability and low friction (important because the phase shifters are in constant motion), flame resistance and stable Dk within climate conditions ranging from –40 deg C to +55 deg C with 55 per cent humidity. And, because the materials are thermoplastic, they are capable of complex geometries and miniaturisation, unlike ceramics or PCBs.

Thermoplastics can also provide higher production yield rates than ceramics, contributing to potentially lower system costs.

Sabic has achieved these results by its superior compounding ability – that is, leveraging a deep understanding of the molecular structure of the base resins and the filler materials to yield the desired performance results.

Sabic’s dielectric portfolio consists of compounds using a variety of base resins, including Lexan resin, a polycarbonate material; Noryl resin, a polyphenylene oxide resin; or high density polyethylene (HDPE) resin, which expands the ability for component manufacturers or system integrators.